Shirogami (White) and Aogami (Blue) Steel: An In-depth Look at Finest Carbon Steels

For connoisseurs of fine Japanese knives and scissors, the names Blue Paper Steel (Aogami) and White Paper Steel (Shirokami) reverberate with respect. These prestigious carbon steels hail from the esteemed Yasugi Special Steel, crafted by the skilled hands at Proterial (Hitachi Metals) Ltd. in the scenic Yasugi City of Shimane Prefecture.

Iron sand from this region is prized for its extraordinary purity. Meticulously refined using the time-honoured "Tatara" technique, the outcome is the legendary Tamahagane steel. Such steel has given life to exquisite Japanese swords for over a millennium, using the guarded techniques of masterful swordsmiths. Proterial (Hitachi Metals), Japan's pioneering private steel company founded in 1899, ensures the continued legacy of this exceptional steel craftsmanship.

SK Material Steel

- HRC Hardness: 58±2

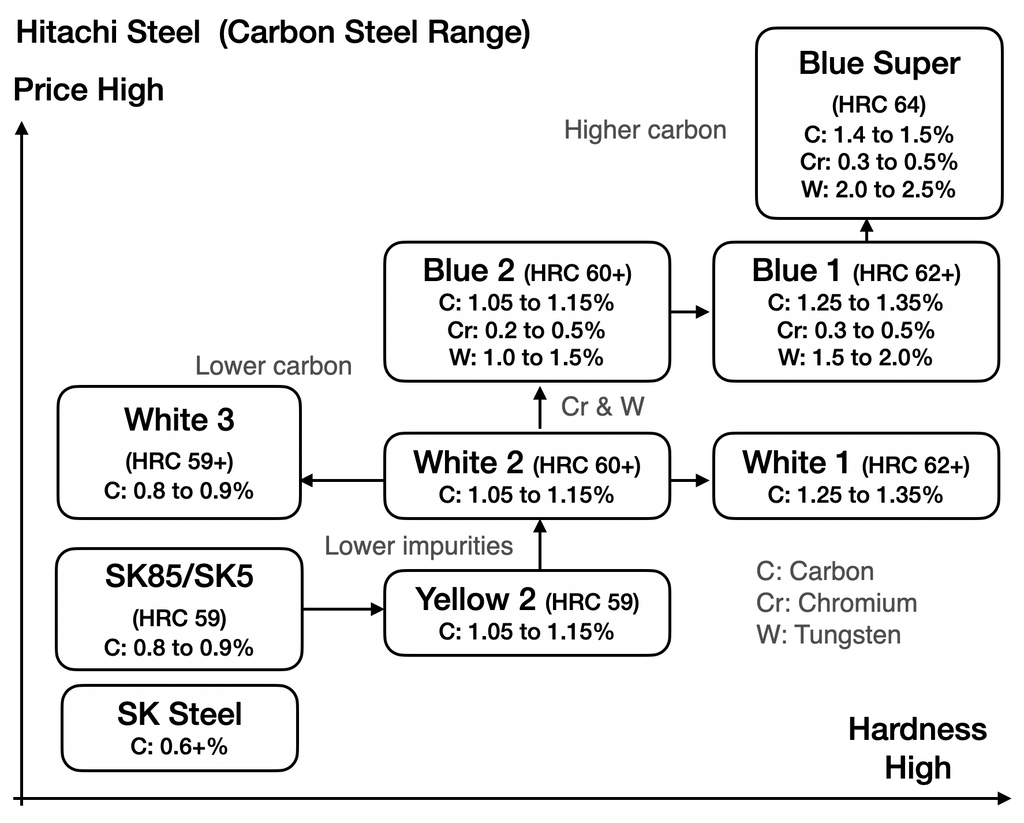

Commonly known as "SK" – a fusion of "Steel" and the Japanese term "Kougu" (Tools) – this carbon steel boasts a robust carbon content exceeding 0.6%. Notably, the SK-85 variant (previously known as SK-5) graces our selection of household knives and scissors.

Kigami: Yellow Label Steel

- HRC Hardness: 58±2

The radiant Yellow Label Steel is a harmonious blend with a generous 50% high-purity iron sand based on the SK's composition. Despite its superior purity, it's tailored for household knives and tools where ultimate durability isn't the prime concern. Cherished for their impeccable sharpness, Yellow Label blades offer affordable excellence. Perfect for household and beginner enthusiasts, their delicate balance of sharpness and durability is hard to resist.

Currently, only Yellow Paper No.2 (1.05-1.15%) is produced.

Shirogami: White Label Steel

White Label Steel emanates from the purest iron sand, showcasing an unmatched purity. Famed for its razor-sharp edge, this steel demands the expertise of seasoned craftsmen to truly shine. Diverse in its offerings, White Label Steel presents multiple variants catering to specific needs, making it the top choice for professionals.

There are different types of White Label Steel based on the carbon content, with White No.1 (1.25-1.35%), No.2 (1.05-1.15%), No.3 (0.80-0.90%), and Saw Material (0.90-1.00%).

White No.1 Steel

Advantages:

- Supreme sharpness among all steels.

- Distinct and exclusive, few craftsmen master its complexities.

Drawbacks:

- Demands exceptional sharpening skills.

- Comes with a premium price tag.

- Care is needed; it is susceptible to rust.

White No.2 Steel

Advantages:

- Consistently sharp.

- Offers excellent value.

Drawbacks:

- Lags slightly behind the Blue Label Steel in edge retention.

- Cautious handling is needed; it can rust if neglected.

White No.3 Steel

Advantages:

- Novice-friendly sharpening.

- Durable with reduced chipping risks.

Drawbacks:

- Not the sharpest in the family.

- Requires attention; prone to rust.

Aogami: Blue Label Steel

- HRC Hardness: 62±1

The majestic Blue Label Steel is made by adding chromium (Cr) and tungsten (W) to the high-purity White No.2. It is a testament to Japanese innovation, with added chromium for resilience and tungsten for wear resistance. It's tougher and less prone to chipping compared to White Label Steel. However, it might make it more challenging to resharpen.

These additions make Blue Steel knives an investment in longevity and performance, striking a harmonious balance between sharpness and edge retention. However, their premium quality is reflected in their price.

Different types of Blue Lable Steel are available based on carbon content, such as Blue No.1 (1.25-1.35), No.2 (1.05-1.15), and Super Blue with added elements (1.40-1.50).

Blue No.1 Steel

Advantages:

- Fluid, consistent sharpness.

- Long-lasting sharp edge.

Drawbacks:

- Demands advanced sharpening techniques.

- A luxury choice with its price.

Blue No.2 Steel

Advantages:

- Retains its sharpness longer.

- User-friendly sharpening, especially with stones.

Drawbacks:

- A premium choice.

- Maintenance is key; it is susceptible to rust.

Blue Paper Super Steel: The Pinnacle of Japanese Knives

Blue Paper Super Steel, manufactured in Japan, belongs to a distinctively high-end category in the realm of knife steel. What sets it apart is its unparalleled hardness and exceptional wear resistance.

A Steel Brimming with Passion and Supreme Hardness

Boasting an impressive hardness level of 67, the Blue Paper Super stands as the zenith of Yasugi steel. But its prowess doesn't end with just tungsten and chromium; the steel also integrates molybdenum and vanadium, elements typically used in stainless steel. This blend imbues the steel with wear resistance that is simply unmatched when compared to other steels.

Hardness is a pivotal factor in ensuring a blade retains its sharpness. With the equation of hardness equating to sharpness, it's no wonder the Blue Paper Super Steel enjoys immense popularity.

A Cutting Edge That's Fiercely Sharp

Its unique composition means that this knife retains its edge for a remarkably long time. The blade's longevity in sharpness is truly commendable.

However, this very hardness makes it a challenge to refine the blade with softer whetstones. Moulding and polishing, be it in its creation or during sharpening, are intricate tasks with this knife. Its structure, dominated by hardness, ensures that even tiny micro-serrations on the edge cut with incredible efficacy. Consequently, it easily tackles even the tougher ingredients without a hitch.

In summary, while the Blue Paper Super Steel knife offers unparalleled sharpness and durability, it demands expertise both in its crafting and maintenance. A worthy companion for those who appreciate the finest in knife craftsmanship.